NEWS CENTER

Present the latest real-time information for you

With the continuous expansion of the decoration industry, tile processing can be said to be the current high-profile investment project. Because of its large market demand, promising prospects and high returns, there are many bosses who want to open a tile processing factory. But to start a processing factory, in addition to the factory building, the factory also has a batch of processing equipment, so what equipment is needed to open a tile processing factory and how much does it cost?

Items that need to be prepared in the early stage of opening a tile processing plant:

First, Plant area requirements:

1. Small general processing plant: more than 100 square meters;

2. Standard ordinary processing plant: about 100-300 square meters;

3. Professional tile processing factory: more than 300 square meter.

4. Real estate construction site processing: more than 50 square meter.

Two, Power requirements:

1. Three-phase four-wire circuit;

2. Power according to the purchased model size: 20-80Kw;

3. The main line of the workshop is 16m²×3+6m²X1 copper wire and above.

Three, circulating pool requirements

1. Build a 3-6m³ circulating pool (please consult customer service for details)

Fourth, the introduction of the equipment model required to open a tile processing plant:

1. Professional all-round tile processing factory:

(1) a set of 2515 five-axis waterjet cutting machine (floor pattern parquet modeling);

(2) One full-automatic arc polishing machine with 14 grinding heads (45° chamfering, round edge grinding, straightening, grooving, chamfering inside corners);

(3) One 1200 CNC three-blade cutting machine (batch cutting, grooving, trimming) does not chip or drop corners;

(4) 1200 type hand push tile cutter (triangular cutting, diagonal cutting)

Four sets of equipment according to configuration low-high total budget: about 330-370 thousand RMB; average daily cutting output: 3000 meters (eight hours), average daily grinding and chamfering output: 5000 meters (eight hours), waterjet parquet output: 800 Meters (eight hours)

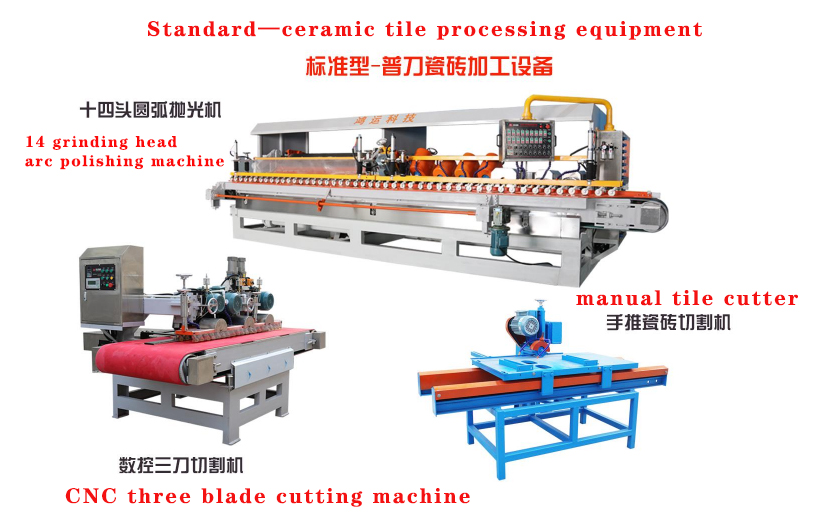

2. Standard general tile processing factory:

(1) One full-automatic arc polishing machine with 14 grinding heads (45° chamfering, rounding, straightening, grooving, chamfering inside corners)

(2) One 1200 CNC three-blade cutting machine (batch cutting, grooving, trimming) will not chip or drop corners

(3) 1200 hand push ceramic tile cutter (triangular cutting, diagonal cutting)

Three sets of equipment according to configuration low-high total budget: about 150-170 thousand RMB ; average daily cutting output: 3000 meters (eight hours), daily average grinding and chamfering output: 5000 meters (eight hours)

3. Small general tile processing factory:

(1) One arc polishing machine with twelve grinding heads (45 degree chamfering, rounding, straightening, grooving, chamfering inside corners)

(2) One set of 1200 CNC three-blade cutting machine (batch cutting, grooving, trimming) without chipping or dropping corners

(3)1200 type hand push tile cutter (triangular cutting, diagonal cutting)

Three sets of equipment according to configuration low-high total budget: around 83-85.5 thousand RMB ; average daily cutting output: 3000 meters (eight hours), average daily grinding and chamfering output: 1500 meters (eight hours)

4. Construction site/micro tile processing equipment:

(1) One 1200 type ceramic tile chamfering machine (45 degree chamfering and polishing, straightening edges, and chamfering inner corners)

(2) One set of 1200 CNC three-blade cutting machine (batch cutting, grooving, trimming) without chipping or dropping corners

According to the configuration of the two equipment, the total budget is low-high: about 66-68,000; the average daily cutting output: 3000 meters (eight hours), the average daily grinding and chamfering output: 1500 meters (eight hours)

The purchase of tile processing equipment should be based on the circuit tolerance of your own plant area. When purchasing our equipment, we will provide free on-site installation guidance and operation throughout the country, and 15 days of super long one-to-one specialists to guide the operation until the customer has mastered the various processing techniques. Technology and equipment maintenance. Welcome to the factory to inspect and test the machine!