NEWS CENTER

Present the latest real-time information for you

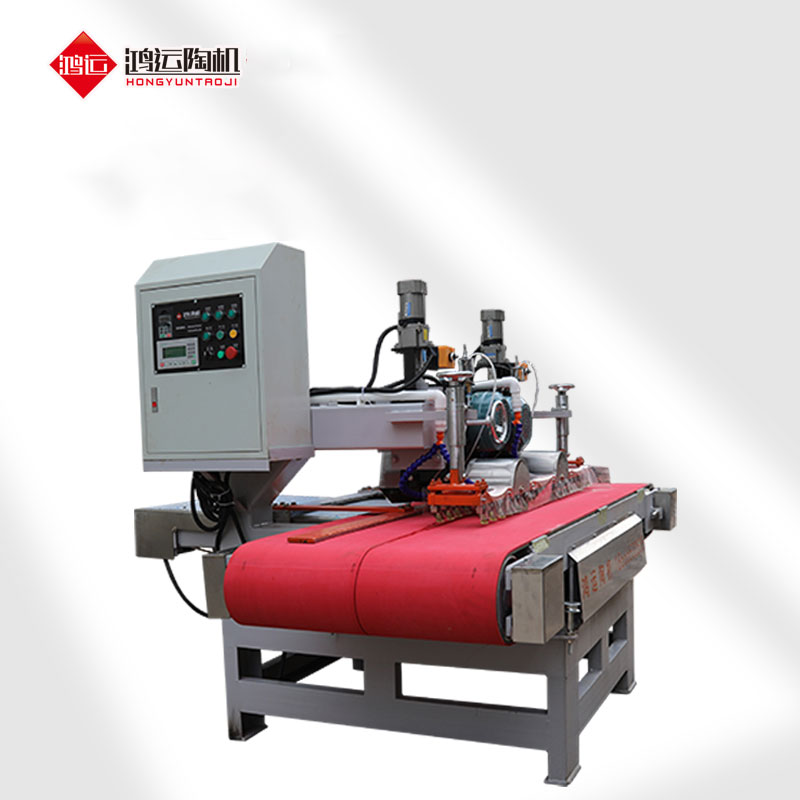

Numerical control ceramic tile cutter is used for cutting and slotting, using digital control size, cutting precision, high speed, high efficiency, more suitable for mass cutting needs of processing plants. CNC size adjustment is very convenient, just input the corresponding number on the control panel, the baffle will automatically locate to the required cutting size, the operation is very simple, CNC ceramic tile cutter solves the problem of complex cutting size. It is one of the advanced ceramic tile cutting equipment, and is favored by ceramic tile processing manufacturers.

Installation instructions of CNC ceramic tile cutter

1. Before using the numerical control ceramic tile cutter, horizontal debugging must be carried out. Put the level meter on the conveyor belt surface, adjust the angle screw, and adjust it vertically and horizontally until it is horizontal.

2. After leveling, tighten the angle adjusting nut.

3. After adjusting the level, it must be installed on the flat concrete floor to minimize the vibration of the machine.

Notes on starting process of CNC ceramic tile cutter

1. The brick cutting master must pay attention to whether the bricks follow the gauge and whether they leave the gauge during the cutting process;

2. Do not press the operation panel randomly in the cutting process. In case of emergency brick breaking, press the red emergency stop button;

3. During the cutting process, do not touch the rollers at both ends of the belt with both hands. Be careful to clamp hands and do not touch the cutting pieces;

Maintenance method of CNC ceramic tile cutter

1. The cutter uses high temperature resistant diesel engine oil. The three blade cutter has three oil cups. Before starting the machine every day (according to the working time of eight hours), add half a cup of oil to the oil cup. (when adding in the oil cup, pay attention to whether the oil cup switch is turned on and whether the oil flows into the cutting shaft);

2. The lifting motor bracket often needs the lifting cutter head. Please add a little oil to the gap on both sides before use. When lifting the cutter head, the screws on both sides need to be loosened first and then lifted. After adjusting the height, special attention should be paid to locking the screws.

3. The first blade of cutting head is 1.6mm thick cutting piece by default, the middle blade is V5 trimming blade, and the third blade is 1.9mm thick cutting piece. It is recommended to use the original cutting piece.

4. The guide screw is oil immersed, and the oil tank shall be checked once half a year to see if there is oil bubble on the guide screw;

5. For the debugged cutter, please do not tamper with the left and right direction of the first cutter and the cutting shaft screw of the third cutter head. (the height of the trimming cutter can be adjusted according to the situation, but the cutter head must not be adjusted disorderly).