NEWS CENTER

Present the latest real-time information for you

Porcelain slab is a new type of decoration material, with various colors, high temperature resistance, low temperature resistance, abrasion resistance, anti-permeation, acid and alkali resistance, zero methanol, environmental protection and health properties, and its operability is also very strong. It can be used for home decoration and commercial projects. Today, let's take a look at what equipment is needed for deep processing of porcelain slabs? And what are the further processing steps?

Porcelain slab can be further processed into kitchen countertops, bathroom countertops, furniture countertops, and can also be used for wall and floor paving, cabinet decoration panels and other applications. What equipment is needed to process porcelain slabs into these finished products? Let’s introduce it below:

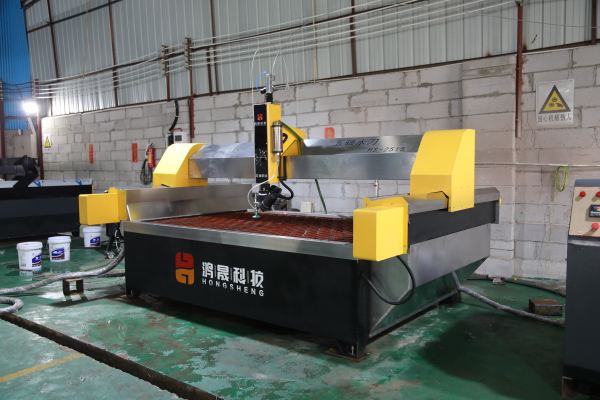

1. Cutting and cutting machine equipment: 4020AC five-axis porcelain slab waterjet cutting machine, various types of manual and CNC cutting machines, and 45-degree cutting machine in the porcelain slab.

2. Waterjet digging equipment: five-axis waterjet cutting machine

3.45 degree cutting back chamfering equipment: 45 degree cutting edge chamfering

4. Polishing and grinding equipment: Model 1800 automatic porcelain slab edging machine, Model 2100 porcelain slab special-shaped edging machine, Model 1200 round table porcelain slab cutting and grinding machine.

What are the specific steps for deep processing of porcelain slabs?

The first step: first cut the porcelain slab into the appropriate size with the porcelain slab cutting machine. In fact, it is cut according to the finished product you want to process, which is what the insider said.

The second step: dig a hole in the cut porcelain slab with a water jet digging device. Be careful when operating this step, otherwise it will break easily.

The third step: Use a 45-degree cutting edge chamfering machine to chamfer the porcelain slab.

Fourth step: Use porcelain slab glue to glue the semi-finished slabs together.

Fifth step: After polishing the semi-finished porcelain slab, it is the finished product.

The above is what equipment is needed for deep processing of porcelain slabs? And what is the introduction of the deep processing operation steps, I hope to help you. If you have more professional needs, you can contact our online customer service (86)152 7835 3800 in Whatsapp. The business manager will recommend the appropriate equipment according to your needs. Welcome new and old customers to inquire.