NEWS CENTER

Present the latest real-time information for you

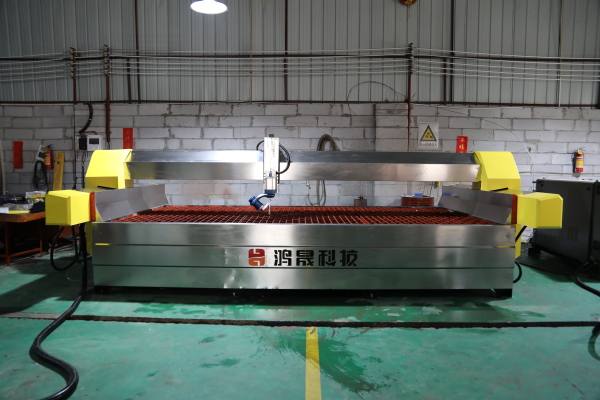

The water cutting machine is widely used in today's cutting industry. Because it can meet the project needs of many companies, it has been favored by major companies. With the continuous development of mechanical technology, a relatively new type of five-axis waterjet cutting machine has been developed on the basis of the original three-axis waterjet cutting machine. So what are the parameter settings of the five-axis waterjet cutting machine?

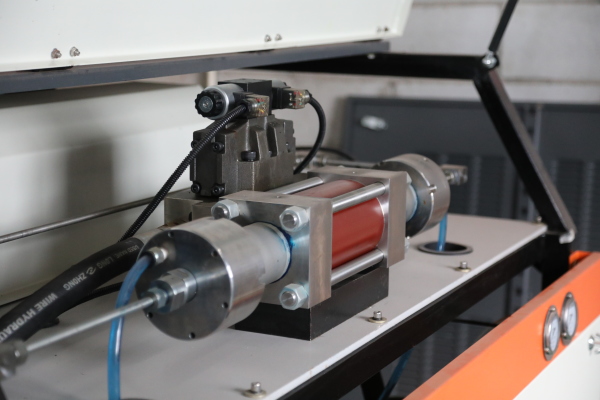

The parameter settings of the five-axis waterjet cutting machine mainly include: AC main shaft cutter head is mainly used for rock slab cutting, the cutter head can cut angle: 0-60 degrees; has a large cutting platform of 4000mm*2000mm; cutting speed can reach 800-2500mmminute , The total power of the motor is 40KW, and the water consumption is 3.7L per minute. It adopts ultra-high pressure supercharger, high-pressure assembly adopts Flow standard, high-pressure cylinder adopts ACC high-pressure cylinder imported from the United States, and 3/8 high-pressure pipe imported from Europe. Brand-new CNC control system, waterjet system uses Shanghai HongWei system. It can be used to cut the rock slab at an angle of 45 degrees to achieve seamless splicing; and the original German imported laser scanner is mounted on the cutting spindle, and the large-size plates are scanned and positioned before cutting, which can ensure the high precision of waterjet cutting Processing requirements The advantage of the five-axis waterjet is that the cutting plane is perfect, and it can cut and process various complex process drawings. Our cutting platform adopts imported screw guide rails, XY uses oil-immersed rails, and an effective dust-proof and waterproof design structure to ensure that the accuracy and stability reach high-performance standards!

Operation process of waterjet cutting machine:

1. Prepare the drawings and raw materials first, carefully check whether the drawings are consistent with the raw materials, open the program to be cut, and check whether the CNC program is consistent with the product to be processed.

2. Check whether the electrical appliances, power supply, and hydraulic oil are normal.

3. Turn on the high-pressure water, circulating water and air pumps to ensure that all are in normal operation before starting up.

4. Open the operating program, press the "drive" button to confirm the zero position, if the position is offset, it needs to be reset.

5. Ensure that the water in the waterjet pool is above the standard line and the amount of water must not be too small.

6. Wear labor insurance glasses to avoid industrial accidents.

7. When cutting different materials, adjust the corresponding speed, pressure and emery flow rate.

8. Emery must be kept dry to avoid sand blocking during operation. When the amount of emery is small, add it in time. Do not use coarse emery during operation. The emery must be sieved with a 60-mesh sieve before use.

9. In cutting, pay attention to whether the cutting is done according to the drawing, and always pay attention to the height of the sand knife to avoid being prone to knife collision.

10. When cutting, always pay attention to the operation of the machine, check the pressure of air and water pressure, whether there is water leakage in the booster cylinder and the conduction line, and whether the motor is heating up

11. Organize the cut semi-finished products, do a good job in overall maintenance and hygiene.

Foshan Nanhai Hongyun Ceramic Machinery Co., Ltd. is a manufacturing enterprise focusing on the field of ceramic deep processing equipment. The company integrates production, sales, installation training-after-sales as a one-stop service, focusing on guiding the establishment of ceramics and stone deep processing plants, leading the industry. Welcome to visit the factory for consultation! .Contact me directly in Whatsapp: +86 15278353800.