NEWS CENTER

Present the latest real-time information for you

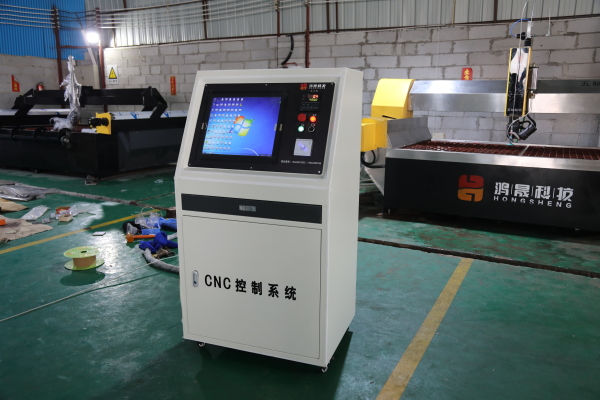

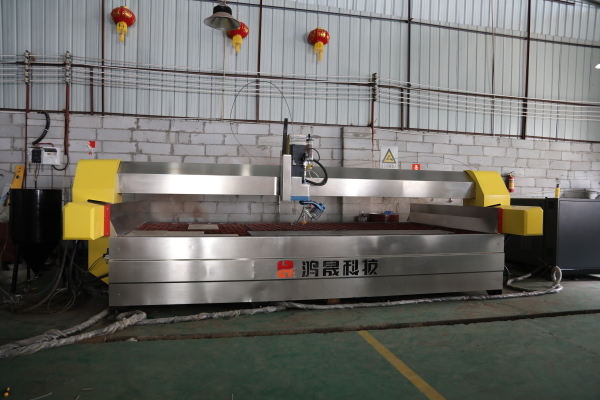

water jet cutting machine is a cutting device that uses ultra-high pressure water jets to cut in a cold state. It has a wide range of applications, from metal materials to non-metal materials, from natural materials to artificial materials, from food to daily necessities, and can basically be cut. It has the reputation of "universal cutting machine". So how to use the CNC waterjet cutting machine?

The operation method of CNC waterjet cutting machine

1. Cutting thick materials

When cutting materials with a thickness less than 2.5, the yield of medium or large cutting heads is not high. If necessary, use small parameter combinations, consider multi-head cutting and increase output.

2. Underwater cutting

Underwater cutting can reduce the fogging of the surface or the upper edge in the process of sand waterjet cutting. Underwater cutting can greatly reduce the noise during cutting and make the working environment more tidy and orderly. The only disadvantage is that the operator cannot see the jet cutting clearly during the cutting process.

3. Smaller abrasive mesh

Smaller abrasive meshes will slightly reduce the speed, but can produce a smoother surface.

4. Air gaps encountered during cutting

Avoid cutting the air gap larger than 0.5 mm. The nozzle is easy to diverge in the air gap, so the surface will be very rough when cutting the lower layer. When stacking and cutting, keep the sheets neatly stacked together.

5. Automatic loading and unloading, most machines do not use automatic loading and unloading technology.

6. Increase or decrease the water pressure through the controller.

7. The waterjet system uses ordinary tap water. 90% of pure waterjet and sand waterjet users only need to soften the water, and then enter the booster through the pump water filter. Reverse osmosis and deionization technology can greatly extend the life of the nozzle, but it can also cause serious damage to the supercharger and high-pressure pipe.

CNC waterjet cutting machine is a plane cutting machine tool that combines an ultra-high pressure water jet generator and a two-dimensional CNC machining platform. It increases the pressure of the water flow to a high enough level, so that the water flow has great kinetic energy, which can penetrate chemical fiber, wood, leather, rubber, etc. When a certain proportion of abrasive is mixed into the high-speed water stream, it can penetrate almost all hard materials such as ceramics, stone, glass, metal, and alloys. Under the guidance of the two-dimensional numerical control processing platform, the machine tool can start or finish processing at any position of the material, and move at an appropriate speed according to the set trajectory, so as to realize the plane cutting of any graphics.If there are any questions,Please contact me (Whatsapp:+86 15278353800).