NEWS CENTER

Present the latest real-time information for you

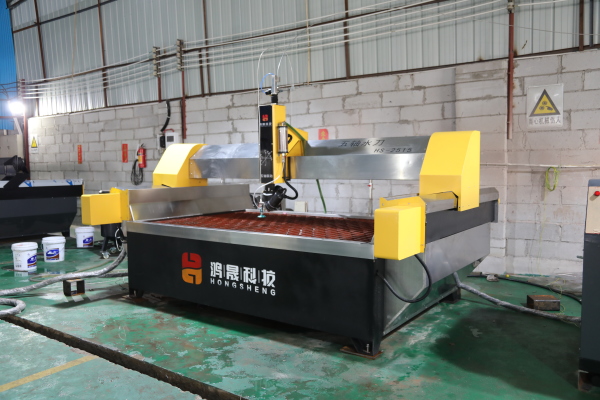

With the rapid development of modern mechanical processing industry, more and more mechanical products require certain skills to operate, so how does the waterjet cutting machine operate?

One,before starting:

1. Prepare the drawings and raw materials first, carefully check whether the drawings are consistent with the raw materials, open the program to be cut, and check whether the CNC program is consistent with the product to be processed.

2. Check whether the electrical appliances, power supply, and hydraulic oil are normal.

3. Turn on the high-pressure water, circulating water and air pumps to ensure that all are in normal operation before starting up.

4. Open the operating program, press the "drive" button to confirm the zero position, if the position is offset, it needs to be reset.

5. Ensure that the water in the waterjet pool is above the standard line and the amount of water must not be too small.

Two, Cutting:

1. Wear labor insurance glasses to avoid industrial accidents.

2. When cutting different materials, you need to adjust the corresponding speed, pressure and emery flow rate.

3. The emery must be kept dry to avoid sand blocking during the operation. When the amount of emery is small, add it in time. Do not use coarse emery during the operation. The emery must be sieved with a 60-mesh sieve before use.

4. During cutting, pay attention to whether the cutting is in accordance with the drawing, and pay attention to the height of the sand knife at any time, so as not to be prone to knife collision.

5. When cutting, always pay attention to the operation of the machine, check the pressure of air pressure and water pressure, whether there is water leakage in the booster cylinder and the conduction line, and whether the motor is heating up

Three. After the cutting is completed:

Organize the cut semi-finished products, do a good job in the overall maintenance of the finished product, and do a good job of hygiene.

Fourth, the operator must carefully study the operating procedures and CNC user manual, without the consent of the superior, any employee is not allowed to change the CNC parameters, and found that the machine has abnormal sound or oil leakage. It must be shut down immediately. And take corresponding measures.

Water cutting technology originated in 1936. Its working principle is that low-pressure water is transformed into high-pressure water through the action of a high-pressure water pump, passed through a high-pressure pipe, and then ejected from the cutting nozzle. Because high-pressure injection is required, the diameter of the water jet is very small. The knife nozzle is generally made of high-grade cemented carbide, gemstones, diamonds, etc. The jetting speed of water is several times the speed of sound. This high-pressure water jet has a strong cutting ability.If you want more imformation about this machine,please contact me directly in Whatsapp:+86 15278353800