NEWS CENTER

Present the latest real-time information for you

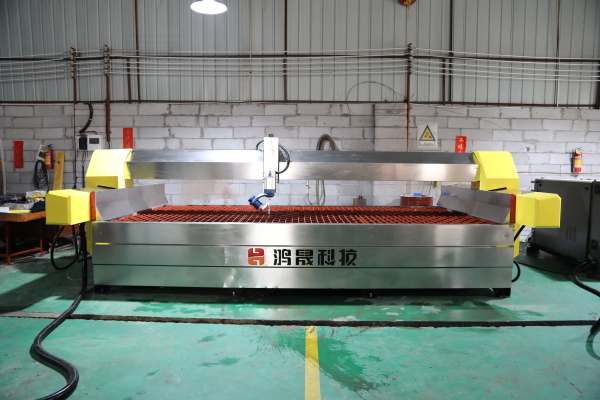

We all know that the waterjet cutter is a relatively expensive processing equipment in the current cutting industry. During the cutting process, it will continue to consume water, electricity, emery, equipment consumables and other consumables. All of these must be borne by themselves. Below About the cost of using the water jet cutter.

1. Water: depends on the pressure and flow rate of the equipment, generally around 3.7L/Min; the level of the water fee depends on the local market price.

2. Electricity: It depends on the overall motor operating power of the equipment. Common waterjet cutting motors have 18KW, 22KW, 40KW, etc.; the level of electricity costs depends on the local market price.

3. Emery: At present, the abrasive used in all water jets is emery. The domestic emery production area is mainly from Xingtai, Hebei. The commonly used emery is 60 mesh, 80 mesh, 100 mesh, etc. The ex-factory price is generally 1.4-6 RMB/kg (the price fluctuates depending on the sand model), and the cost of sand transportation needs to be borne by the customer. It depends on its own situation. In some places, such as Guangdong and Zhejiang, the unit price of sand is more than the ex-factory unit price of sand. It's expensive.

4. Sand pipe: The highest quality ceramic carbide sand pipe can provide 150 hours of cutting time, while the diameter is only 0.020".

5. Consumables for vulnerable parts of the equipment: This depends on the long-term use pressure (related to the type, thickness and processing requirements of the cutting process), the time of starting work every day, the type, quantity, and price of the vulnerable parts of the equipment, etc.

6. Regular maintenance: that is, regularly changing the water jet control system, cutting platform, high-pressure generator and sand box parts, etc.

water jet is a very prominent cutting equipment in the cutting industry. Regardless of the technical characteristics or production capacity, water jets have more advantages than other cutting methods. The water cutting method not only produces no heat, but also produces no harmful gas. It is a typical high-efficiency, multi-functional cold cutting processing method. In this cold working process, the ultrasonic water jet produced by the water jet can achieve the desired effect when cutting the surface of the material. The mixing of water and sand further enhances its cutting ability. In addition, in order to better reduce costs, water cutting technology can effectively reduce costs and achieve greater profits.