NEWS CENTER

Present the latest real-time information for you

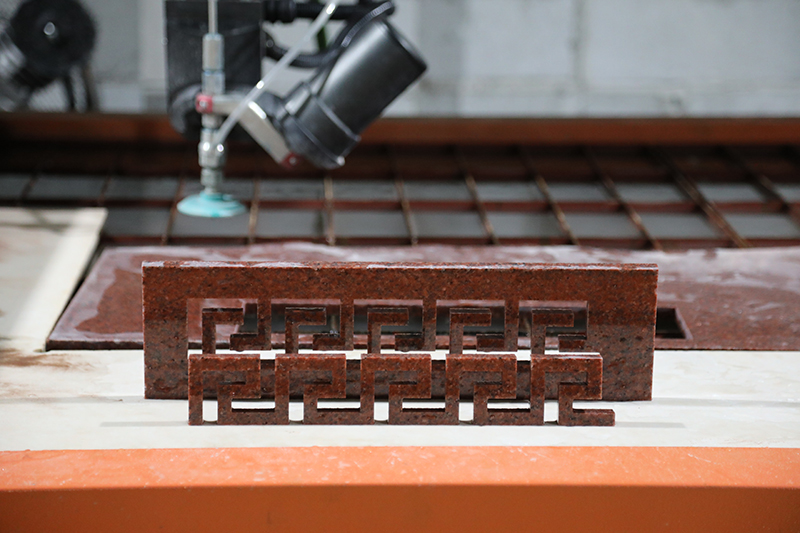

With the development of machinery technology, people's aesthetics for craft decorations are constantly improving. Many machinery manufacturers are also facing many unique challenges. How to ensure the flexibility of the machine while cutting out more functions, the quality is better and does not require manual operation .At present, water cutting and laser cutting are the most suitable processing equipment for these conditions. The advantages and disadvantages of waterjet cutters and laser cutters are introduced below.

The advantages and disadvantages of waterjet cutting

Advantages: The water jet can cut most materials. After being cut, the incision is smooth and will not produce rough edges with burrs. Using water and abrasive cutting, the process of processing reduces the thermal deformation of the material, and the generated pollutants can be directly discharged. The biggest advantage is that one nozzle can process different types of materials and shapes, the moving speed is fast, and the incision is fine, it can process very precise parts, and the accuracy is very good.

Disadvantages: A large amount of water and sand are needed during the processing, which leads to high cost of use, short life of the original parts, and high maintenance costs.

Advantages and disadvantages of laser cutting:

Advantages: Laser cutting can obtain better cutting quality, the precision of the incision can reach ±0.05mm, the cutting surface is smooth and beautiful, no mechanical processing is required, and the parts can be used directly. And equipped with multiple numerical control worktables, the entire cutting process can be fully numerically controlled. There is no contact between the cutting torch and the workpiece during cutting, and there is no tool wear. The operation process has low noise, low vibration and no pollution.

Disadvantages: The material being cut by laser cutting and its properties usually limit the applicability of certain cutting mechanisms, auxiliary gases and laser types. Equipment generally consumes more power and energy than other cutting processes, and it releases potentially harmful and toxic gases when cutting plastic. These emissions require air pollution control equipment and increase costs.

The above is the advantages and disadvantages of waterjet cutting and laser cutting introduced by the editor. You can choose different cutting equipment according to your cutting needs. If you need to buy waterjet cutting machines can go to Foshan Nanhai Hongyun Ceramic Machinery Co., Ltd, or contact me directly in Whatsapp: +86 15278353800.

pre_product: Water consumption of waterjet cutter Cost of using waterjet cutter

next_product: Small ceramic tile processing equipment price