NEWS CENTER

Present the latest real-time information for you

With the development of my country's machinery industry, various cutting technologies have matured, and there are more and more cutting methods, such as waterjet cutting and plasma cutting. So what is the difference between waterjet cutting and plasma cutting? Which of the two cutting techniques is better?

Comparison of waterjet cutting and plasma cutting:

1. Cutting accuracy

Compared with the plasma cutting machine, waterjet cutting has obvious advantages in cutting accuracy. The current plasma cutting accuracy is between plus or minus 0.4-1 mm.

2. cutting material

At present, plasma cutting can only focus on metal material processing. For example, glass, ceramics, chemical fiber, stone, wood can not meet the demand, which leads to the main reason that there is still a certain market for water cutting.

3. cutting speed

The high efficiency and high speed of plasma cutting is unmatched by water cutting, such as general plasma cutting, the cutting speed can reach 2000MM-3000MM/MIN, which far exceeds the water cutting speed.

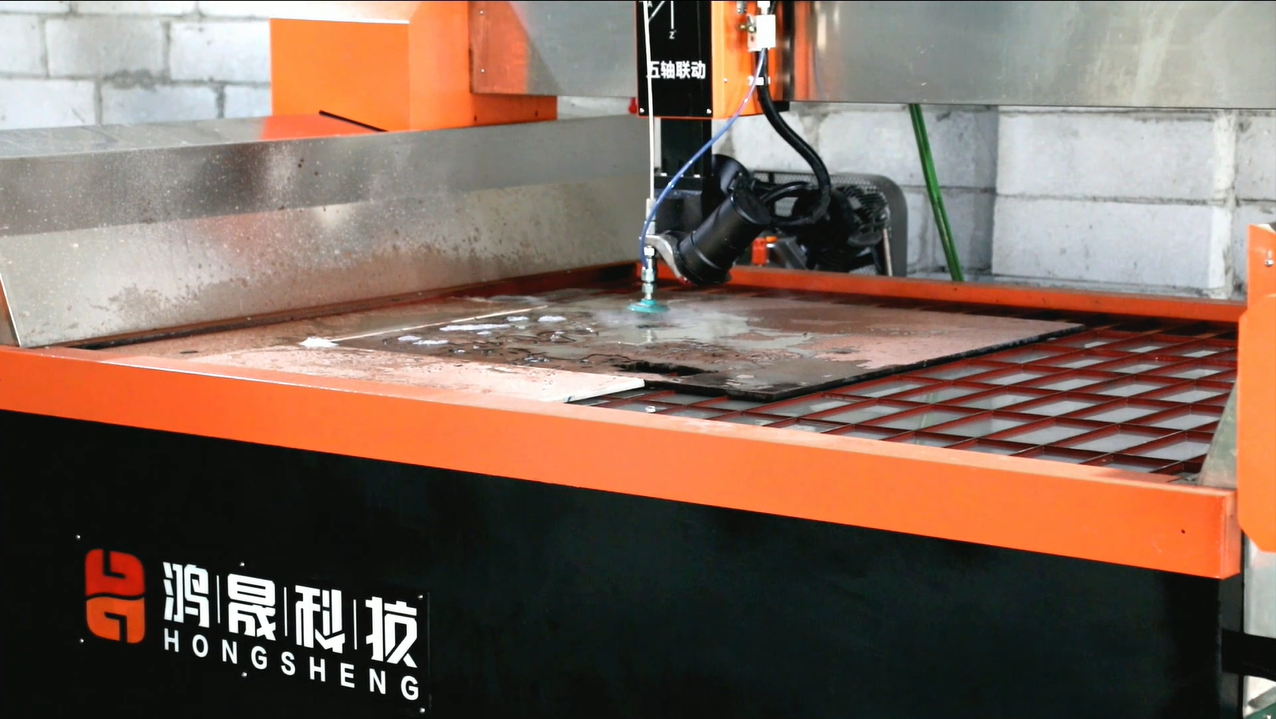

The waterjet cutter is capable of numerically forming various complex patterns. It is a kind of cold cutting. There is no thermal deformation or thermal effect during the cutting process, and it is environmentally friendly and pollution-free, and does not produce toxic gases and dust. The incision is smooth, there is no slag, and no secondary processing is required. The drilling, cutting, and forming work can be completed at one time, with low production cost and high degree of automation.

Plasma cutting has better cutting effect on non-ferrous metals, and the cutting speed is fast, especially when cutting ordinary carbon steel thin plates, the speed can reach 5-6 times that of oxygen cutting, the cutting surface is smooth, the thermal deformation is small, and the heat affected zone is less .

The choice of machinery mainly depends on the configuration and model you choose, the size of the cutting platform, whether it includes tax, freight, after-sales service and a series of issues. When purchasing, you must negotiate with the manufacturer.