NEWS CENTER

Present the latest real-time information for you

The hand-push ceramic tile cutting machine is a electric ceramic cutter. Compared with other non-electric ceramic tile cutters, the hand-push ceramic tile cutter is more accurate, convenient, fast, environmentally friendly, safe, energy-saving and practical. It is suitable for straight line cutting and angle cutting of all kinds of glazed tiles, vitrified tiles, hard polished tiles, glass, etc. The hand-push type ceramic tile cutting machine is divided into two kinds of single blade cutting machine and double blade cutting machine.

Hand-push single-blade CNC ceramic tile cutting machine

The hand-push CNC series cutting machine is the latest development of Hongyun. It adopts H steel support + linear guide rail and oil bubble guide rail. The accuracy can reach within 0.1mm and the life span can reach more than 6 years. Its main functions are cutting and grooving.

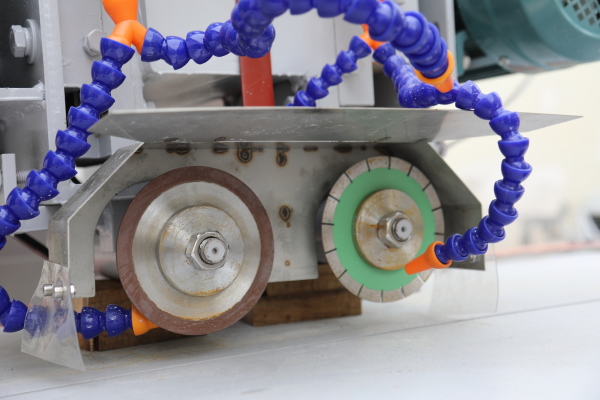

Hand push type double blade CNC ceramic tile cutting machine

Double-blade CNC cutting machine is a special trimming blade added by Hongyun to the single-blade basis. It can be cut directly with trimming, no porcelain chipping, no corner drop, etc., H steel support + linear guide, the degree can reach 0.1mm Within the error, and the life span can reach more than 6 years, it is one of the necessary products of the ceramic tile processing factory. Its main function is cutting, trimming and grooving.

Hand-push CNC double-blade cutting machine operating instructions

First, Tools and maintenance supplies that need to be prepared:

1. A set of allen wrenches, 2 17-19 wrenches, a 30-32 wrench, and a barrel of diesel engine oil 18 liters;

Two, Connecting water and electricity:

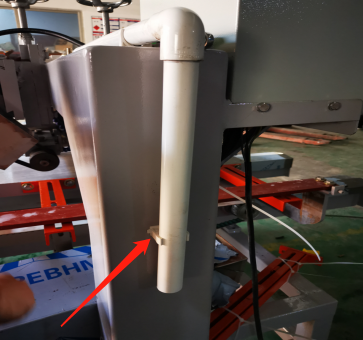

(1) Connect 1 inch of water (as shown below)

(2) Wiring needs to be connected: three-phase four-wire, three live wires + one neutral wire (N is the neutral wire) (as shown below)

Third, Add diesel oil before starting up:

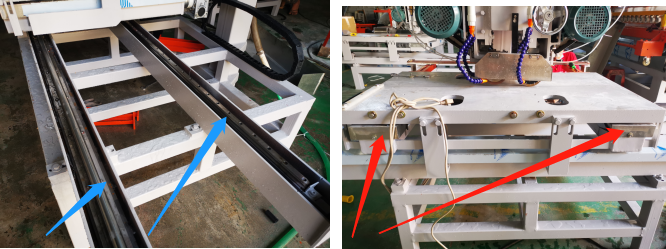

The guide rail oil is soaked + the screw rod oil is soaked + the oil can is full (the oil can is turned on every day, plus 1/5 a small amount) (as shown below)

Fourth, the use steps of CNC operating system:

(1) After connecting the electric line, turn on the emergency stop, test the machine, and the blade is reversed;

(2) Enter the operation interface (as shown in the figure below)

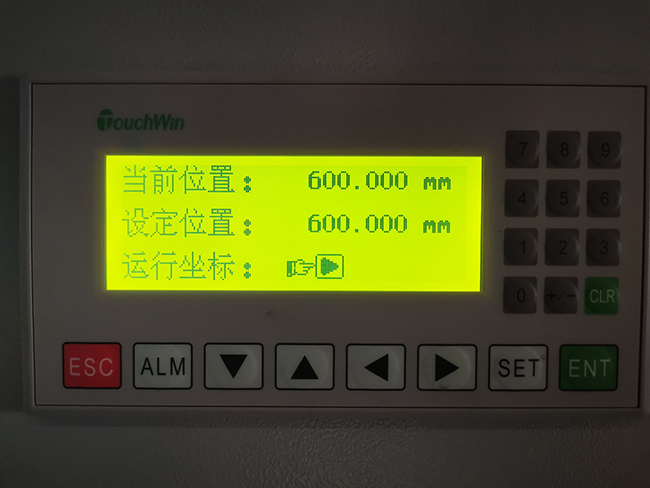

(3) Find:The interface of current position and set position (as shown below)

(4) Press the [SET] key, and after seeing the black background light up, enter the size you want to cut (for example, when cutting 10 cm, it is: 100.000mm, pay attention to three 0 decimal points, don’t make a mistake!) (as shown below)

![Press the [SET] key.png Press the [SET] key.](http://www.newworldcn.com/uploadfile/ueditor/image/20210608/1623157931387695.png)

(5) After inputting the size, press the [ENT] key, and then press the "running coordinate" right arrow [] as shown in the figure

![Press the [ENT] key.png Press the [ENT] key.](http://www.newworldcn.com/uploadfile/ueditor/image/20210608/1623157902632430.png)

Five, The numerical control system data is inaccurate, and the recovery method:

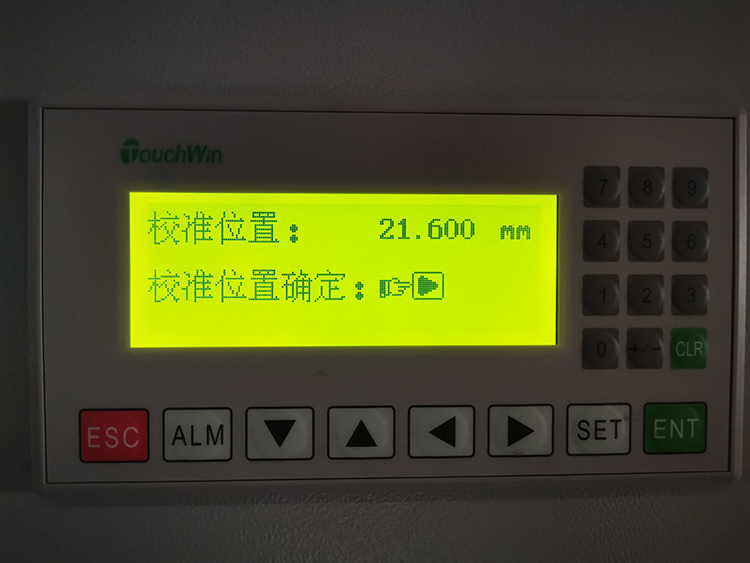

Step 1: Cut a piece of brick arbitrarily, measure the size, and then the second step is as shown in the figure below:

(1) Press the ↓ key, turn the page to find the [Calibration Position] page;

(2) Press the [SET] key, input the measured size just now, press the [ENT] key to confirm, and then press the [] key to confirm.

![Press the [SET] key.png Press the [SET] key.](http://www.newworldcn.com/uploadfile/ueditor/image/20210608/1623157624622373.png)

Six , How to change the blade:

The working principle of the ceramic tile cutting machine is to use the physical characteristics of the arrangement of the fired ceramic crystals to uniformly cut the cutting line on the surface of the ceramic tile with a cemented carbide cutter wheel, and then use the principle of mechanical lever to conduct the mechanical force along the cutting line and break it. Just like cutting glass, the cutting efficiency is extremely high.