NEWS CENTER

Present the latest real-time information for you

With the continuous development of mechanical technology, rock slabs have gradually integrated into people's lives. Many ceramic tile processing factories are very unfamiliar with the processing and application of rock slabs and the replacement of some parts of rock slab cutters. For example, the replacement of cutting blades. So how to replace the cutting blades of rock slab cutters? Let's take a look at it together.

Cutting blade replacement steps for rock slab cutter:

1. Choose the corresponding type of cutting blade, or configure different types of cutter blades according to the ceramic tile cutter motor.

2. When installing the blade of the ceramic tile cutter, the horizontal line should be kept flat, which can extend the life of the cutting blade and increase the yield of ceramic tiles.

3. Install it to test whether the cutting effect is good, use waste tiles on the cutting panel for precise size adjustment, and see if the ceramic cutting effect can meet the standard.

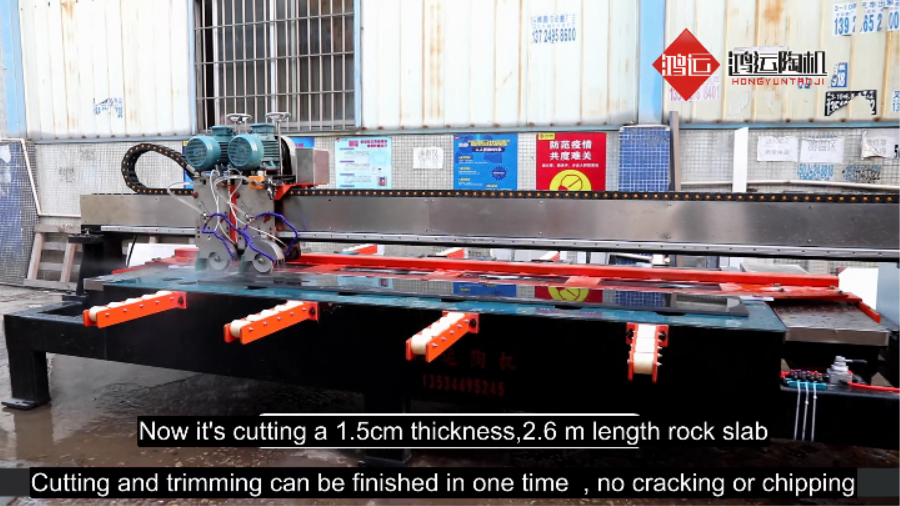

The characteristics of 3200 type rock slab CNC cutter:

1. High precision of CNC adjustment

The error is within ±0.1mm. Double cutter head (first cutter trimming, second cutter cutting), no chipping, no corner drop, high stability!

2. the rock slab cutting is fast and convenient

The cutter head is raised and lowered electrically,one key numerical control adjusts the size, which can realize automatic typesetting and cutting.

3. double spindle sawing motor

Adopt brand new sawing spindle motor 4KW (domestic, can be customized according to requirements: imported), high-power spindle motor (Note: the difference between spindle motor and ordinary motor: the spindle motor can be directly equipped with cutting blades, no jitter, ordinary motors need to pass ordinary motors The cutting shaft is driven by a belt to realize cutting when the saw blade is installed. This structure will be bounced, which will cause a certain damage rate of the board.)

4. key smart typesetting

One-key smart typesetting, you can automatically cut with a blade, double-cutting with trimming and no ceramic collapse.

5. Quenching treatment of the whole machine

The main body of the machine tool is specially treated by quenching, and the whole machine structure is integrated. The machine tool is not easy to deform and has a long life.

The main function of HY-3200 rock slab CNC cutter is to complete CNC precise cutting and trimming at one time. It has the characteristics of no chipping and no corner drop. It is mainly used for rock slab ceramic slabs, cutting straight line cutting, and the maximum cutting can be 3.2 Taking 15mm rock slab as an example, the cutting speed can reach 2.5-3m/min: it is widely used for cutting materials in rock slab processing plants.

pre_product: The use method and precautions of desktop tile cutter

next_product: The latest multi-function ceramic tile cutter price query