NEWS CENTER

Present the latest real-time information for you

With the continuous development of ceramic deep-processing machinery, there are more and more types and specifications of machinery, and the processing technology of machinery is becoming more and more advanced, and its functions are becoming more and more comprehensive. It can be seen that ceramic processing machinery is a kind of high-precision equipment, and it is also a product built strictly in accordance with the characteristics of ceramic tiles.The following is an introduction to the installation process of ceramic processing machinery.

The installation of ceramic processing machinery needs to ensure that the ground is flat, and all angles of the machine must be flat after installation, otherwise the processing effect will be affected. Ensure the correct power connection, such as foreign special industrial voltage 415V/50HZ, 220V/50HZ, 220/60HZ. If the power supply is connected incorrectly, it may cause the motor on the ceramic processing machine or the electrical appliances in the electrical cabinet to burn out. If a leakage protection switch is required, one needs to be installed. Ceramic processing machinery works in the presence of water and electricity. Customers should judge whether the circulating pool provided by the factory has sufficient water supply based on their processing capabilities.

After the ceramic processing machinery is installed correctly and completed, the processing can be started. It is best to strictly follow the instructions and processing procedures to avoid unnecessary production. Secondly, to ensure timely maintenance, this is the only way to extend its service life.

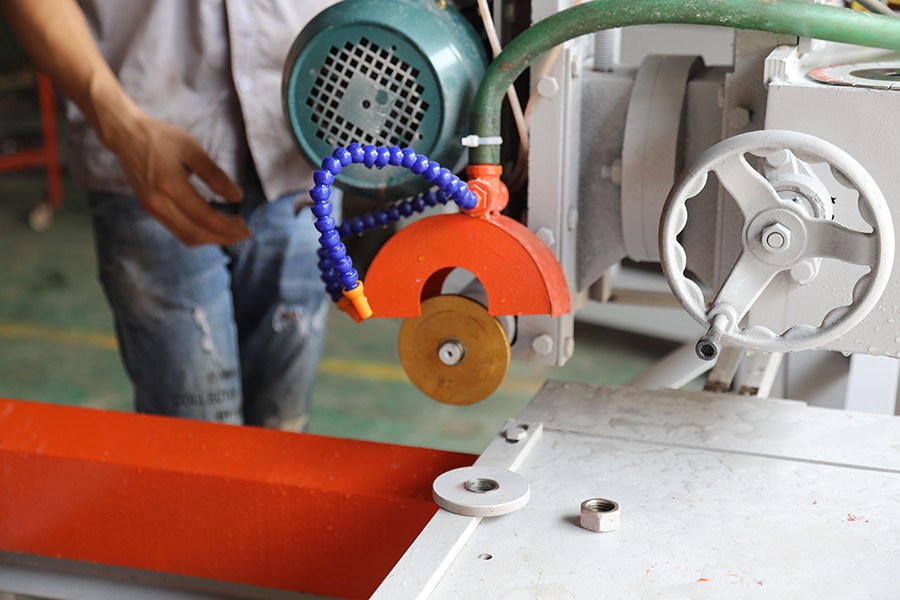

Ceramic processing machinery is one of the earliest ceramic tile deep processing equipment. Mainly used for cutting, edging, chamfering, grooving, arc grinding, polishing, step tile processing, skirting tiles, etc. To make some special-shaped tiles, and according to people's different needs and tile positioning, the most ideal state can be processed,which is durable, precise and efficient. If correctly and reasonably used, it can not only ensure normal production, but also prolong the life of the machine.

Now our social needs are constantly expanding, so are ceramic processing machinery. There is a market where there is a need. Foshan Hongyun Ceramic Machinery Factory boldly innovates, and the mechanical equipment developed by it has been well received by many new and old customers. At present, the technology of ceramic processing machinery is progressing rapidly, and the development trend is integration, large-scale, continuous, high-speed, precision, automation, process, numerical control, ultra-miniaturization and technology-intensive. The contradiction between advanced ceramic tile processing machinery and backward maintenance capabilities will increasingly plague enterprises and become an obstacle to their development.If you are interested in these machine,please contact me in Whatsapp or email(whatsapp number:+86 152 7835 3800;email:hymachinery00@gmail.com)