The 800 double group continuous cutting machine is mainly used for cutting skirting tiles and mosaics.It is a ceramic tile cutting machine that can cut multiple sizes and 7-8 strips at once , and is one of the indispensable processing equipment for ceramic tile processing plants. This machine is dual-axis simultaneous cutting, and each nose can be equipped with multiple blades. It is suitable for dividing large-size wall and floor tiles into the required strip tiles, square tiles, diamond tiles, etc. ,and the processing size is 20-800mm. Using the method of pre-cutting and then cutting off , it is possible to divide tiles of different widths at one time , increase production, and without damage. It is widely used in skirting lines processing and mosaic slotting. It can be used for cutting 2-12 pieces tiles, and it can also be used for slotting flat groove , V-shaped groove,with fast speed, good stability in the process of processing, labor saving, low cost, is definitely a good helper for processing plants.

1. The performance and characteristics of product:

(1) This machine adopts double-group multi-blades cutting,the first blade pre-cutting and the second blade cutting off,which reduces the cutting stress and greatly reduce the edge chipping and breakage of cutting;

(2)When processing small mosaics, press and stabilize the plates to ensure that the processed small plates will not fly out ;

(3)The bearing seat of the spindle box is lubricated with spindle oil and water-cooling device, so it can be used continuously for a long time without heating and high temperature, thus prolonging the service life of the bearing;

(4) Adopts "V"-shaped belt to ensure precise belt conveying;

(5)Dovetail groove lifting, double support gantry structure,which is more stable and less vibration during cutting.

2. Technical parameters:

Conveyor belt width | 820mm | Belt speed

| 0.8-4.0m/min |

Diameter of blade

| 150-300mm | Maximum cutting thickness | 30mm |

Spindle motor power

| 15kw | Total power | 42 kw |

Weight

| 2600kg | Size | 2600*1780*1630mm |

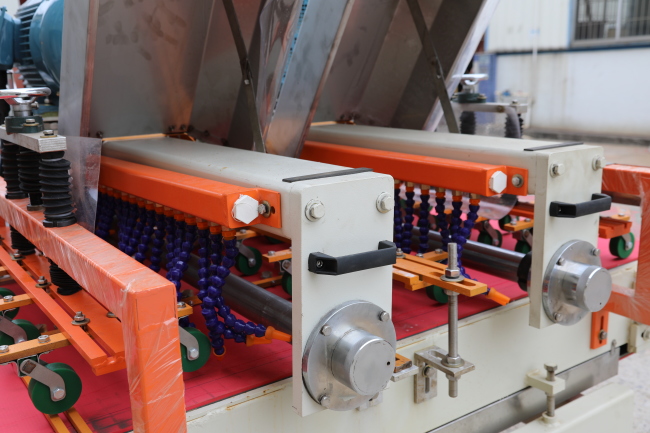

3. Equipment display:

4.The processing machine: