NEWS CENTER

Present the latest real-time information for you

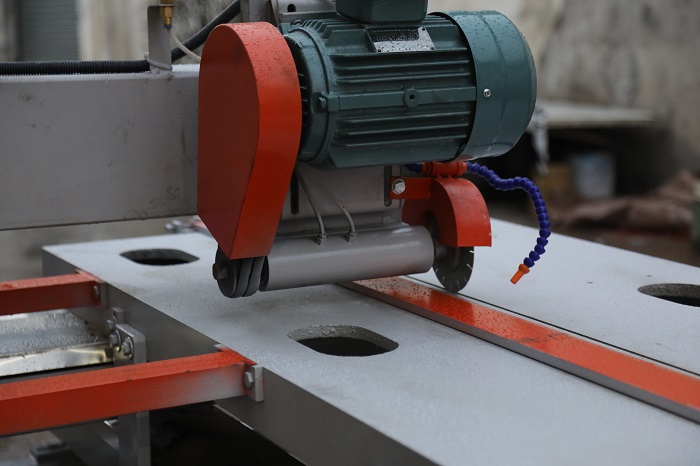

There are many common problems in ceramic tile processing equipment, such as notch in the cutting surface , different cutting size, the processed size is different from the previous batch, and many small porcelain avalanche after cutting. What are the reasons for these problems? How to solve it?

1. After cutting, notch are found on the cutting surface

Cause analysis: most of the ceramic tiles are cut with blades, the physical properties of all magnetic vitrified tiles are relatively brittle, so it is inevitable that there will be a little edge collapse when cutting.

Solution: 80-90% of the fine porcelain edge chipping caused by cutting can be eliminated by edge grinding.

2. The tiles are cut into different sizes

Cause analysis: there are three cases, one is not cutted by the same machine, the other is that the abrasive changes when cutting, the third is that the cutting is not operated by the same person.

Solution: if the situation is not very serious, such as 300 * 600 brick size does not exceed 2mm, the operator can deal with it on site; If it exceeds 2mm, it can be reprocessed to the same size with ceramic processing equipment.

3. The chamfer size is inconsistent with the previous batch

Cause analysis: chamfering is not operated by the same person. Even if operated by one person, the air pressure parameters of the first chamfering are not consistent, resulting in inconsistent pouring angle.

Solution: take the first processed brick back to the processing plant and process it according to the previous air pressure parameters.

4. After the edge grinding of the processing plant, there are still many small porcelain chippings caused by cutting

Cause analysis: when the machine is running, the internal air pressure parameter is not very high, so the trimming angle will not be very large, but there will be more burrs.

Solution: first, the use of caulking agent can be covered up. Second, increase the air pressure parameters, the chamfer is slightly larger, but it may affect the appearance because of the angle is too large.