NEWS CENTER

Present the latest real-time information for you

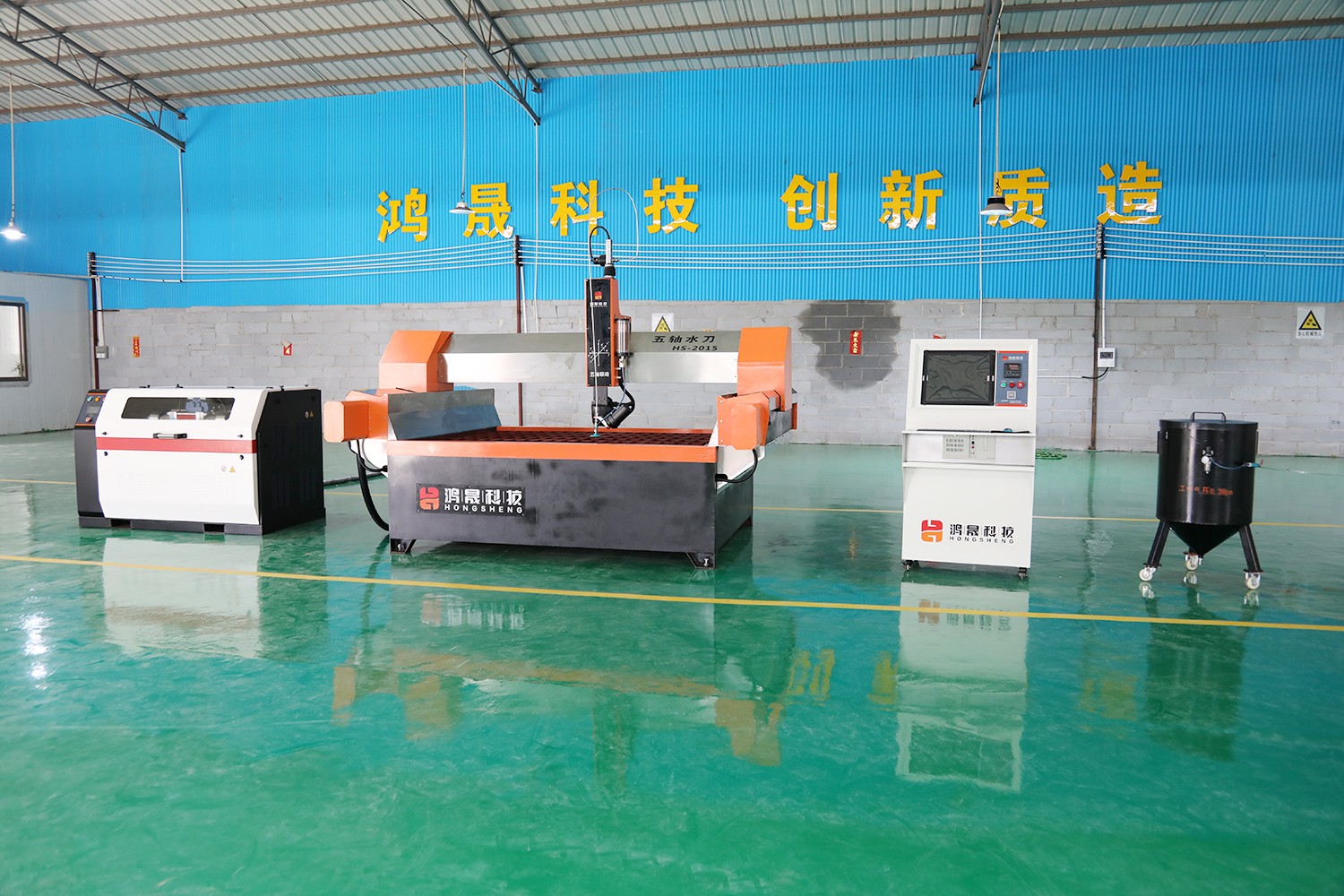

With the rapid development of mechanical technology, waterjet products have entered our lives. We all know that the application of waterjets is very wide, ranging from daily appliances to large aviation businesses that cannot be done without waterjets. But if the machine is used for a long time, there will be some failures. This requires professional maintenance personnel to repair, so what are the common failures of the waterjet cutting machine?

1. the cutting speed is slow

Check whether the sand pipe is blocked or high-pressure pipeline. Sometimes the inner hole of the sand pipe is partially blocked by impurities, resulting in low water flow and slow cutting. You can install the sand pipe up and down (same as the high-pressure pipeline). High pressure.

2. the high pressure water tank is broken

The high-pressure water tank ruptures, causing the high-pressure cutting water to be sprayed out. This phenomenon belongs to metal fatigue. The operation should be stopped and the high-pressure water tank should be replaced immediately.

3. the stroke of the turbocharger is unstable

One side of the one-way valve is leaking. You can disassemble the valve core and valve pad and grind it. If necessary, replace the valve core and valve pad and reinstall the one-way valve. The best way is to maintain or replace all the one-way valve accessories; Foreign impurities enter between the one-way valve core and the valve pad, remove the end cover, remove the pollution source to avoid the problem from recurring, carefully check the one-way valve, and remove any foreign impurities, if necessary, re-maintain the one-way valve and clean all parts And re-assemble; the reversing drive cable or related parts are worn or bent (mechanical reversing), remove the reversing drive cable, install spare parts and check again, replace any worn parts; high pressure water plunger and oil pressure The separation of the piston will also reduce the pressure and flow of the water to avoid serious damage to the supercharger if it continues to operate under this condition. Remove the hydraulic cylinder and piston, and replace the damaged parts; the direction of the water outlet check valve core is reversed , Disassemble the water outlet check valve body, take out the check valve core, and reassemble it in the correct direction.

Waterjet cutting technology is a machine that uses high-pressure water jets to cut. Under the control of the computer, the workpiece can be sculpted at will, and the material texture is less affected. Because of its low cost, easy operation, and high yield rate, water cutting is gradually becoming the mainstream cutting method in industrial cutting technology.If you want more imformation,please contact me directly in Whatsapp:+86 15278353800.