NEWS CENTER

Present the latest real-time information for you

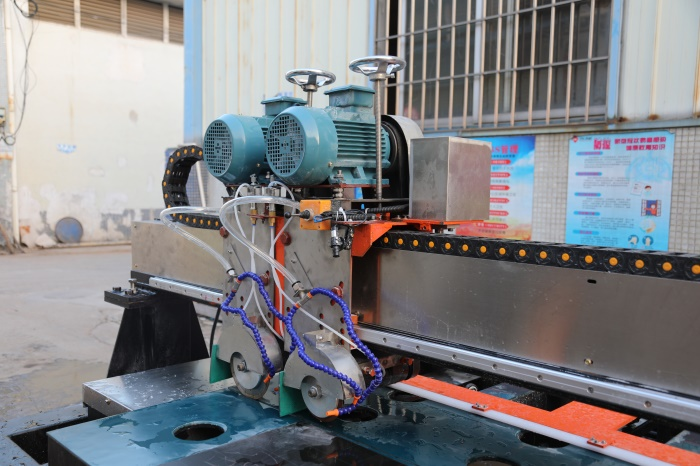

The drive and feed requirements of the CNC rock slab cutting machine strictly guarantee the following characteristics, including: position accuracy and fast response. Usually the motor can realize stepless speed regulation. Stepper motor AC servo motor and DC servo motor. The above three kinds of motors can realize feed drive, but due to the economic and efficiency influence, they are used in different fields.

At present, although the stepping motor is easy to control and low in cost, it is eliminated due to out-of-step and limited speed. DC servo motors are widely used in our country because of their excellent performance, strong overload capacity, easy smooth speed regulation, large braking and thermal torque. The ideal drive component is an AC servo motor, which is easier to maintain and simpler than a DC motor. However, the control is cumbersome, it is difficult to adjust the speed in a wide range, and it is difficult to meet the requirements of continuously variable transmission. When using different drive components, the feed mechanism of the CNC machine tool is also different.

The connection between the motor and the screw is basically divided into three forms

(1) Gear rotation

Generally, the mechanical feed devices of CNC machine tools mostly use gear transmission pairs to meet the expected deceleration requirements, and the gears generally do not meet the strict technical requirements of the ideal tooth surface in the manufacturing process, so proper tooth side clearance must be retained for normal operation, but at the same time , The tooth side clearance will cause the vector momentum on the opposite side of the feed motion system. Therefore, in order to minimize the backlash of the gear transmission pair, elimination measures are generally selected. However, a machine with such a connection structure will become relatively complicated.

(2) Timing pulley

That is to say, for the feed motion coupled in this way, the mechanical mechanism is relatively simple. Synchronous pulley transmission has the advantages of chain transmission and belt transmission, which can achieve accurate transmission ratio, relatively stable transmission, almost no tension is required, at the same time, the shaft end pressure is small, the transmission efficiency is high, and the base wood can maintain 98% around the base. Transmission efficiency. Timing pulleys can realize high-speed transmission because of their thinness and lightness, and the belts with pulleys have better elasticity. When selecting a pulley with a smaller diameter, the entire structure can be made more compact, effectively reducing the vibration and noise caused by the gear transmission, and making maintenance more convenient [13]. But its disadvantage is that the timing belt wheel is only suitable for some mechanisms with lower torque requirements, and the accurate center distance must be ensured during installation. The manufacturing process of the timing belt and the belt wheel is more complicated.

(3) Coupling

The coupling of the coupling meets the requirements of high transmission height and high transmission accuracy of the feed motion system. At the same time, it effectively simplifies the structure of the feed motion system. Therefore, this connection method is generally used in the feed motion system of machining centers or precision CNC machine tools.