NEWS CENTER

Present the latest real-time information for you

The water jet has strong versatility, the cutting medium is only water and natural abrasive, and no other substances are produced in the cutting process. After cutting, the cutting surface is neat and smooth, in the cutting process will not cause any damage to the object to be cut, can carry out a lot of cutting operations that the cutter can not reach.

Introduction of waterjet cutting machine components:

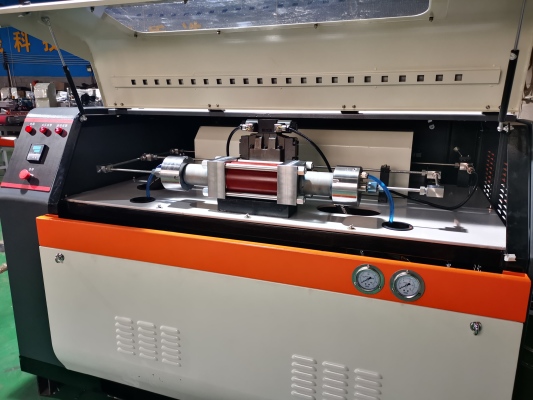

1. Ultra high pressure water pump.

The ultra-high voltage system is mainly used for ceramic, stone, glass, metal, water-cooled cutting and pressurization assembly. The main motor is 37KW. The main components of the high voltage generator are imported materials.

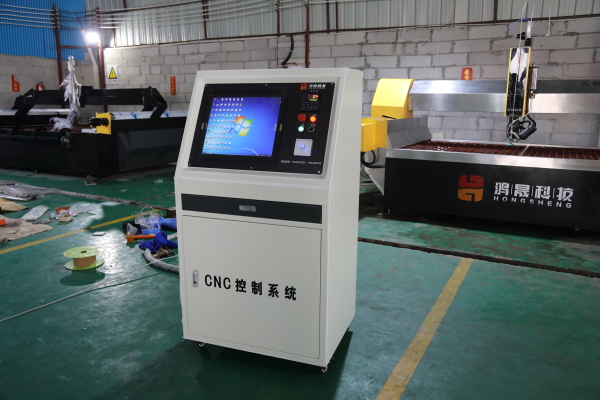

2. Numerical control system

It is composed of high stability industrial computer and high precision multi-function numerical control subsystem. It provides hardware equipment for multi-level signal generation, transmission and feedback control of the whole set of water jet equipment from man-machine interface to multi axis precision linkage of machine tool.

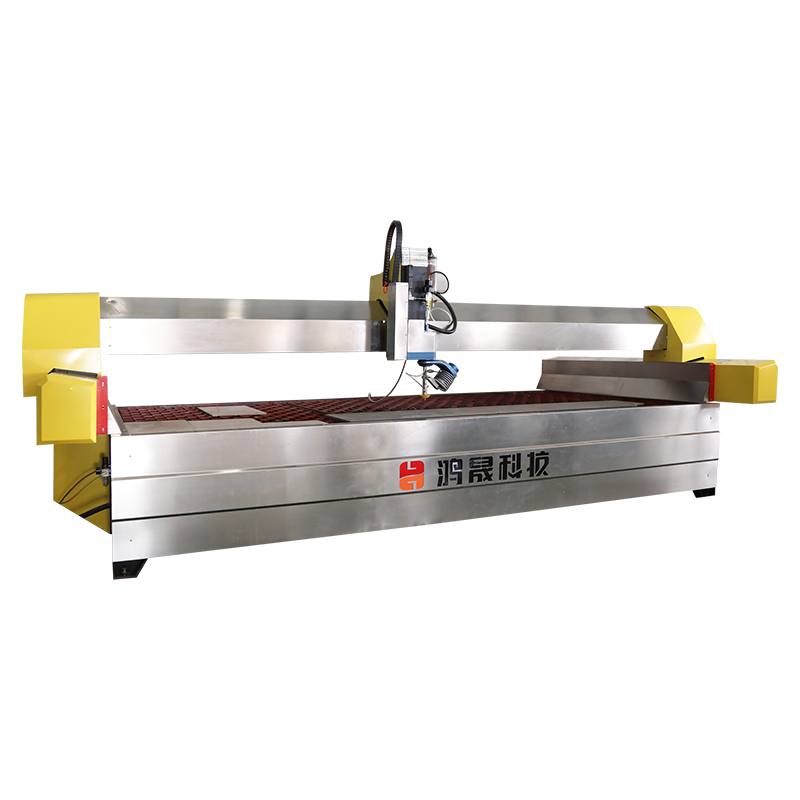

3. Cutting platform

The cutting platform of waterjet cutting machine is cantilever type. It consists of a water tank and a movable beam. The cantilever platform is open on three sides to facilitate the cutting, loading and unloading of large materials. Especially when the material to be cut is larger than the desktop, the material can still be supported or suspended outside the desktop, and then the interior of the desktop can be cut. In addition, because the cantilever or platform water tank is a split structure, it is not only conducive to the transportation of larger platforms and machine tools, but also conducive to the replacement of old and new water tanks.

Water tank: the water tank of waterjet cutting machine is made of stainless steel. It is mainly used for cutting water, sand and debris. The tank is filled with water to protect the bottom of the tank from water jet damage.

Walking part: the walking part of waterjet cutting machine is composed of high-precision ball screw and linear guide, driven by servo motor, and the pneumatic cutter head is installed on the beam.

Cutting head: there is a high-pressure water valve in the cutting head of the water knife cutting machine. The opening and closing of the water valve is controlled by the compressed air switch automatically or manually controlled by the numerical control system. It can be used for pure water and mixed sand cutting.

4. Automatic sand supply system

When cutting hard materials, hard garnet sand is usually mixed in high-pressure water jet for cutting. A small sand bucket is installed on the die beam of the cutting platform to cut small pieces in a short time. More sand should be used when cutting large blocks. When the automatic sand supply system is started, the sand can be automatically supplied to the small sand hopper from the sand supply system. The system automatically detects the empty sand bucket and full sand bucket to start and stop the sand supply. The sand supply is powered by compressed air.

Waterjet cutting is the use of high-pressure water cutting machine. Under the control of the computer, the workpiece can be carved at will, and the material texture has little influence. Because of its low cost, simple operation and high output, water cutting has gradually become the mainstream cutting method in industrial cutting technology.