NEWS CENTER

Present the latest real-time information for you

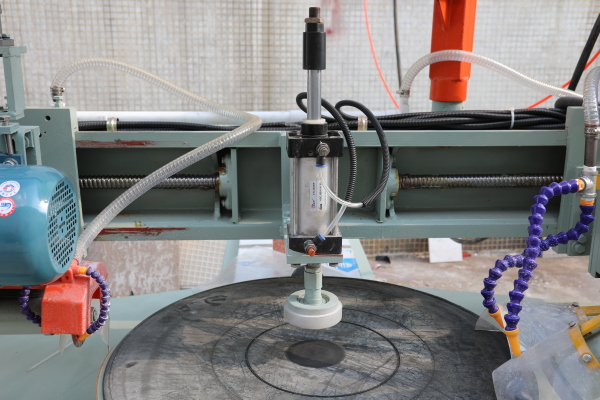

The 45-degree sintered stone cutting and grinding machine is mainly used for sintered stone and ceramic tile round tables. It is specially used to cut round tables with chamfered one-time forming. It is fast and stable. It can be achieved without secondary processing. The following is the 45-degree sintered stone. The advantages and operation of the cutting and grinding machine.

The advantages of 45-degree sintered stone cutting and grinding machine:

The 45-degree sintered stone cutting and grinding machine can complete cutting, edging, and chamfered safety surfaces at one time. It does not need to be transported back and forth. The whole machine has high production efficiency. The cutting size of the machine is precisely adjusted by CNC, and the air pressure is used for edge and chamfering. Polishing, taking an 800mm round table as an example, the cutting and edging polishing will take about 4-5 minutes to complete. It is a model specially designed for sintered stone round table by Hongyun sintered stone machinery factory, which is suitable for cutting and edging processing of sintered stone round table.

The operating method of the 45-degree sintered stone cutting and grinding machine:

1. After mechanical installation, check the tightness of each part, check whether the belt is tight and whether the motor shaft is parallel.

2. Before starting, turn the pulley by hand to check whether the machine is running flexibly and normally, whether there is a collision between the shells, whether the direction of rotation of the roller is correct, and whether the motor and bearings are well lubricated.

3. Don't change the pulley casually to prevent the speed from being too high or too low.

4. After the machine starts, it should run idling for 2-3 minutes.

5. When feeding, it should be unified, and don't keep putting it all the time. If noise, bearing, body temperature is too high or materials sprayed out during mechanical work, stop the machine immediately for inspection and troubleshooting.

6. If there is abnormal noise during operation, check whether the lubricating oil is sufficient, whether the main motor belt is too loose, and whether the nut for clamping the tool is tightened.

7. If the conveyor belt runs smoothly or shifts during processing. Adjust the balance between the two rollers by adjusting the screws at both ends of the conveyor belt, straighten the roller and the edge of the conveyor belt into a straight line, and adjust the tightness of the roller pressure appropriately.

8. If the conveyor belt is found to be unbalanced, check whether the stepless reducer is normal or the conveyor belt is too tight.