NEWS CENTER

Present the latest real-time information for you

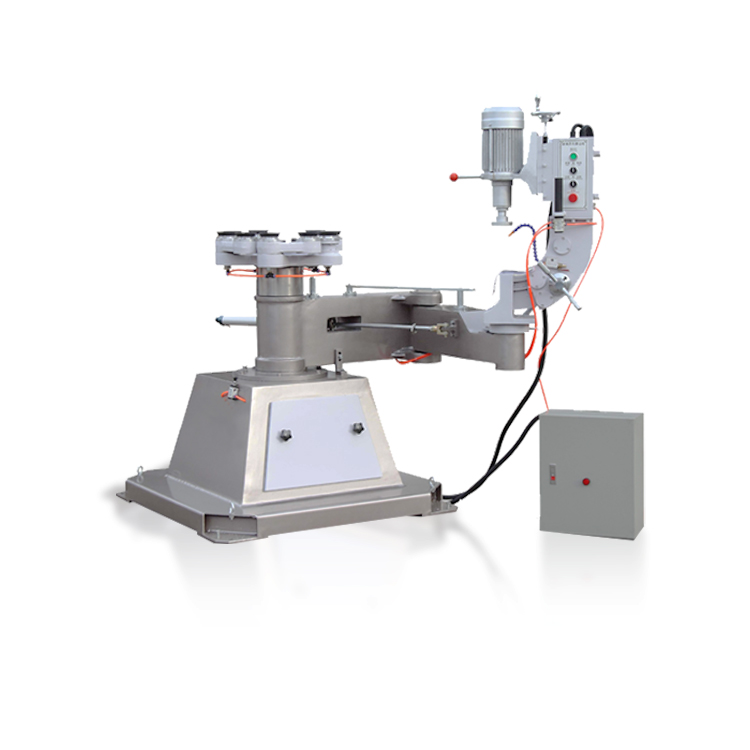

Everyone knows that the porcelain tile edging machine is a machine specially designed for edging of porcelain tiles. It can perform edging, rounding, chamfering, edging, polishing and other functions on porcelain tiles. Many porcelain tile processing manufacturers want to buy such porcelain tile edging machine, but they am afraid that it will not work well. Let me introduce it to everyone.

At present, the most widely used porcelain tile edging machines in porcelain tile processing plants are porcelain tile special-shaped edging machine and porcelain tile round table cutting and grinding machine. These two equipments are mainly aimed at porcelain tile edging and integrated edging. , The inverted safety surface is completed at one time without the need for the second process. The machine has high production efficiency. The adjustment size is precisely adjusted by CNC, and the air pressure is used for edge grinding and chamfering. It adopts a fully automatic working mode, which saves more labor. It is a cost-effective multi-purpose equipment for processing porcelain tiles.

Operation method of porcelain tile edger:

1. Before operating the porcelain tile chamfering machine, you should carefully read the instruction manual provided with the product, and must be equipped with trained full-time personnel to work, and it is forbidden to operate on the machine by unfamiliar and untrained personnel.

2. Before starting the machine, please carefully check whether the mechanical, electrical, pneumatic devices and cooling system of the machine are normal. If any abnormality is found, stop the machine immediately and report to the professional maintenance personnel, and then start the machine after troubleshooting.

3. Regularly check the installation and use of the grinding wheel, fasten and replace the grinding wheel in time; before placing the porcelain tile, adjust all the setting parameters and the position of the grinding wheel, and check whether the thickness and width of the processed porcelain tile are consistent with the set value.

4. Regularly check the lubrication of the mechanical transmission system, replace the lubricating oil in time, and clean the glass debris in the water tank when replacing the polishing liquid.

5. Always keep the electric control cabinet clean and ventilated. It is strictly forbidden to hit the electrical cabinet or pile up debris in the electrical cabinet.

6. When the machine is working, it is forbidden to open the door of the electrical cabinet and the base of the machine to avoid adverse consequences. When entering important workplaces, you should wear safety clothing, gloves, glasses, rain boots and raincoats, which are necessary for operating the porcelain tile chamfering machine.

Have you seen how useful a porcelain tile chamfering machine is and how easy it is to operate? Hurry up and pick up the phone to contact our business manager (86)152 7835 3800(same number on Whatsapp)