The manual ceramic tile inner corner cutting machine is designed for tile 45 degree cutting, without size limit. The biggest feature of this machine is that it does not require frequent adjustment of the size guiding plate and adopts an automatic pneumatic pressure plate device.The machine can cut the minimum 3 cm bilateral 45 degree angle, and easily cut all four sides of tiles. The working platform is easy to push by hand. The processed tile begonia corners have no size head, and no cracking.It is favored by tile processing factory and construction site.And the machine adopts linear guide rail with high precision. There are two models: model 1200 and model 1800, you can choose according to your needs.

1.The performance and characteristics of product:

(1) For the four sides of different sizes, there is no need to repeatedly adjust the size, and the size adjustment problem can be solved at one time;

(2)Adopts oil-immersed high-precision linear guides, which has high precision and no size head;

(3) Adopts 3.0 kw high-power cutting motor, high-speed cutting, no cracking;

(4) Adopts Pneumatic pressure plate device;

(5)The main body of the machine tool is specially treated by quenching, and the whole machine structure is integrated, which is not easy to deform and has a long service life.

2. Technical parameters:

Working table size | 1200*700mm

| Maximum chamfering size | 1200mm |

Diameter of blade | 190mm

| Motor power | 6KW/set

|

Chamfering thickness range | 6-30mm

| 45 degree cutting speed | 3000-6000 rpm |

Size setting method | size guiding plate | Tile fixing method

| pneumatic pressure plate |

Chamfering speed | 2-3m/min

| Weight | 850KG

|

Size | 2600*1500*1600mm | ||

3.Equipment display:

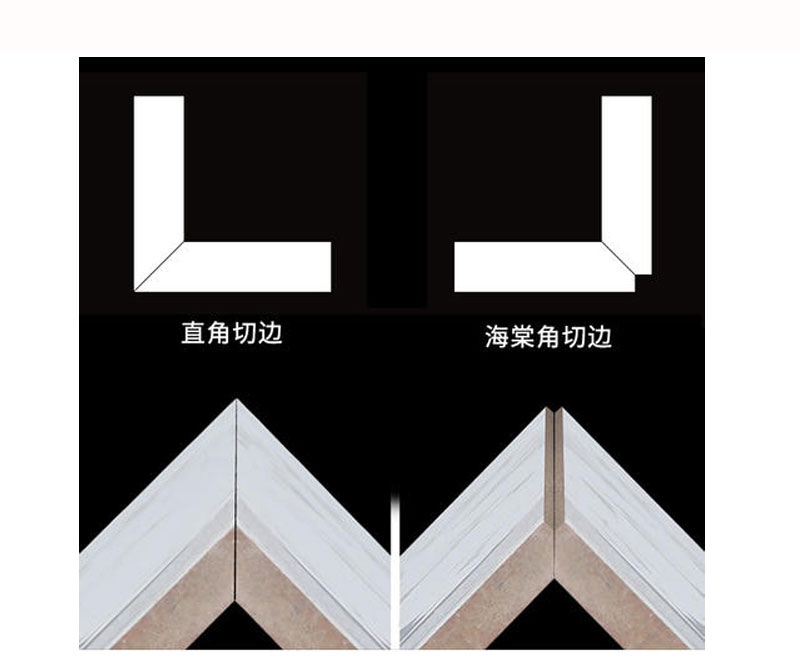

4. Processing effect: