NEWS CENTER

Present the latest real-time information for you

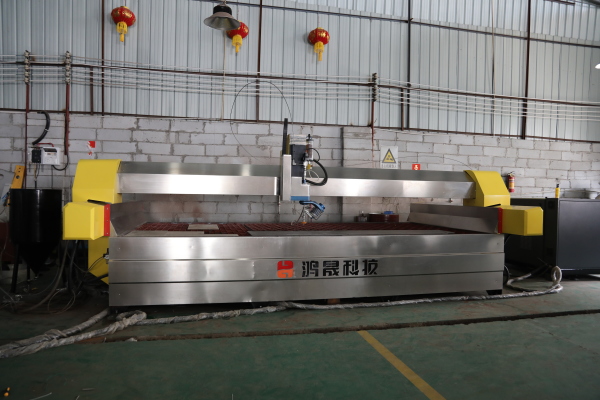

Water jet cutter is a cutting equipment that uses ultra-high pressure water jet for cold cutting. It mainly consists of ultra-high pressure water jet generator (high pressure pump), CNC machining platform, jet cutting head, sand automatic supply system and cooling system.

1. Ultra-high pressure water jet generator (high pressure pump)

As the power source of the waterjet, a common technical solution is a hydraulic motor driving a supercharger to generate an ultra-high pressure water jet. The pressure of ordinary tap water is increased to tens to hundreds of MPa (1 MPa is approximately equal to 10 bar), and it is ejected through a beam nozzle with extremely high kinetic energy.

2.CNC machining platform

CNC waterjet is mainly used for cutting flat plates. The cutting platform uses rolling linear guides and ball screws as transmissions. Under the precise control of the CNC program and the control motor, the X-axis and Y-axis can be moved individually or in two-axis linkage to drive the cutting head to achieve linear and arbitrary curve cutting.

3. jet cutting head

The high-pressure pump can realize the cutting function only through the beam nozzle. The size of the nozzle aperture determines the pressure level and the flow rate. At the same time, the nozzle also has an energy-gathering effect. There are two basic forms of jet cutting heads: one is for pure water cutting, and the other is for cutting with abrasives. The cutting head with abrasive cutting is based on the pure water cutting head, plus an abrasive mixing cavity and a hard nozzle.

4. Sand supply system

It is usually called the sand supply tank, which uses the principle of air pressure to transport sand from the sand supply tank to the sand storage container through the sand pipe to make the sand enter the cutting head so that the equipment can continuously supply sand when cutting.

5. cooling system

In order to keep the engine in the proper temperature range under all working conditions. The cooling system should not only prevent the engine from overheating, but also prevent the engine from overcooling in winter.

The application range of waterjet cutter is very wide, from metal materials to non-metal materials, from natural materials to artificial materials, from food to daily necessities, basically can cut, known as the "universal cutter".