NEWS CENTER

Present the latest real-time information for you

Porcelain slab is a new type of decoration material, which can be deep processed into a variety of finished porcelain slabs, which is very popular with consumers. The market demand for deep-processing products of porcelain slabs is increasing, and the technical requirements for deep-processing porcelain slabs are getting higher and higher. Today we are mainly going to understand what are the 3 key points that must be mastered in porcelain slab cutting processing technology?

What are the cutting processing technologies for porcelain slabs?

1. Before processing the porcelain slab, you must first know the size of the cut and what the finished product needs to be processed before processing. For example: To make a kitchen countertop, it is necessary to leave at least 50 mm from the boundary of the countertop with holes or grooves. Similarly, at least 50 mm should be reserved between two adjacent openings. Draw an arc length of at least 5 mm in radius at each corner to disperse the pressure.

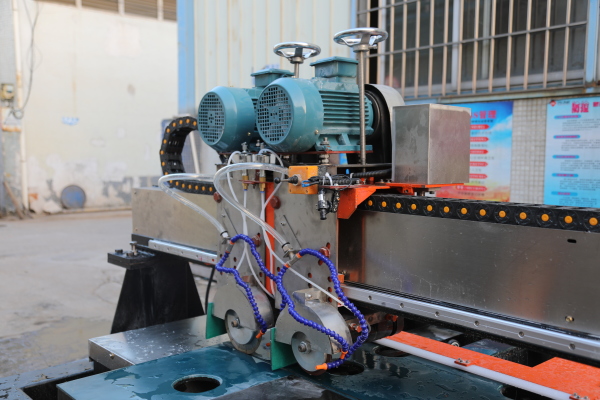

2. Before preparing to cut the porcelain slab, be sure to check the machine equipment and the working table. The parameters of the machine and equipment must be adjusted well, and the workbench of the machine must be completely level. There must be no previously processed waste on the workbench of the machine, and everything is normal on the surface. Therefore, it is recommended that before cutting processing, processing operators take samples for actual testing and actual adjustments to achieve the best results.

3. When cutting porcelain slabs, be sure to use diamond cutting blades suitable for special cutting blades for porcelain slabs. Both U-shaped cutting blades and toothless saw blades can be used. During the cutting process, the porcelain slab must be fed in the same direction as the cutting piece rotates. The cutting opening is proportional to the thickness of the cutting blade. The smaller the radius of the cutting blade, the greater the spindle speed. The slower the feeding speed, the better the cutting effect. The slow feeding speed can ensure the reduction of edge chamfering, and the feeding and discharging speed should always be 50% slower than the rated speed.

The above is an introduction to the 3 key points that must be mastered in the porcelain slab cutting processing technology. I hope to help you. If you have more professional needs, you can contact our online customer service in Whatsapp:(86)152 7835 3800. The business manager will recommend the appropriate equipment according to your needs. Welcome new and old customers to inquire.