NEWS CENTER

Present the latest real-time information for you

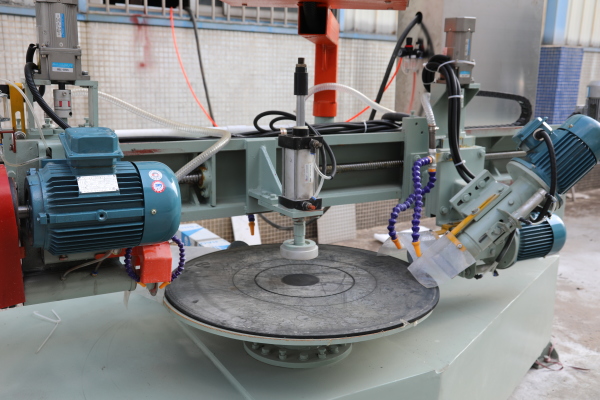

The tile cutter is currently mainly used for the cutting and processing of ceramic tiles, sintered stones, marble and other materials. When you decide to open a tile processing shop, the tile cutter is one of the indispensable equipment for the processing shop. You know how to choose a good tile cutter?

When you want to buy a ceramic tile cutting machine, you will find that there are many processing equipment sellers and various brands on the market. There are so many different models, a mixture of different fish and dragons, and different prices. Everyone says that their products are good, which makes you dazzled and difficult to distinguish. Makes you don't know how to choose?

1. Main parameters: cutting efficiency

Cutting efficiency directly affects the speed of making money. If a shop/factory has enough orders but not enough productivity, what restricts us to make money is the cutting efficiency of processing equipment. The higher the cutting efficiency, the lower the processing cost, the lower the overall production/processing cost of a ceramic tile product, the more money you can make than the peers, and the more competitive.

2. Main parameters: cutting accuracy

Cutting accuracy is the basis for choosing a machine tool. It refers to the contour accuracy of the cut workpiece, not the static accuracy marked on the sample! The final processed product must be in full compliance with the customer's requirements. The decoration product of ceramic tiles requires a specific size. The combination of multiple tiles requires each tile to be the same size. If the cutting precision of the ceramic tile processing equipment is not enough, the processed ceramic tiles will be of different sizes, which will affect the reputation of the shop/project.

3. Main parameters: service life

Everyone hopes that the products they buy are of good quality and low price, and have a long service life. After all, ceramic tile processing equipment is not cheap. If the service life is very short, the second purchase will definitely be distressed. Therefore, the length of life is an indicator of saving money. The longer the life of the equipment, the lower the overall operating cost and the higher the profit margin.

4. Main parameters: maintenance cost, stability

Maintenance cost includes time cost and capital cost. If the maintenance time cost of the purchased equipment needs to be more than that of other brands, then the cost performance needs to be considered, after all, time is money. The stability of the equipment, fewer problems, and low maintenance costs are one of the main factors that need to be considered when purchasing ceramic tile processing equipment.

For more information click our official website:Foshan nanhai hongyun ceramic machinery company.If you are interested in this machine,please contact me in Whatsapp or email(whatsapp number:+86 152 7835 3800;email:hymachinery00@gmail.com)