NEWS CENTER

Present the latest real-time information for you

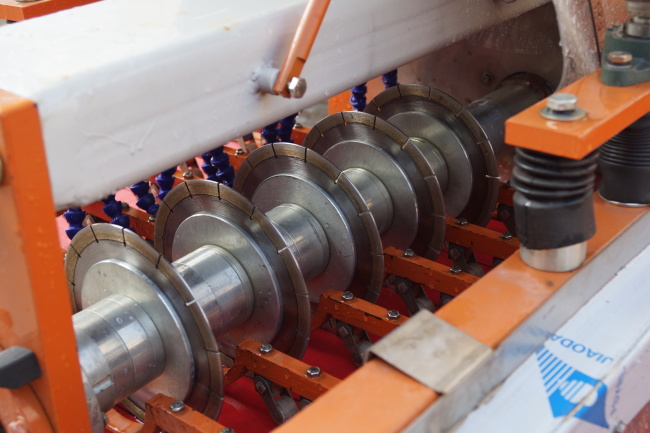

Everyone knows that there are many types of ceramic tile processing equipment, and the operations of each type are also different, so how to safely operate the tile cutter? What issues should be paid attention to in the work process?

Precautions before turning on:

1. Before starting up, please pay attention to check whether the water has been boiled, whether the water volume is large enough, and whether the water volume is sprayed on the cutting disc.

2. Check whether the cutting blade has worn out. Generally, the service life of the cutting blade is 400-600 meters, and then check whether the height of the cutting blade and the trimming knife have been adjusted; the special reminder is that the lifting blade should not exceed the maximum pallet stroke!

3. Check whether the pressure of the pressure roller is at a normal height. The default height is 5-8mm from the belt (the height is determined according to the thickness of the brick).

4. The most important step is to check that the red conveyor belt has no deviation. (Inspection standard: the brick must follow the gear ruler as normal. If you leave the gear ruler, the belt deviation needs to be adjusted and the belt can be cut. , Otherwise there will be inconsistencies in the cutting bricks, the size of the head).

5. Adjust the cutting speed, the default cutting speed: 10-12; the highest limit cannot exceed: 20; and adjust the relevant cutting size, and then turn on the machine.

Operation precautions during the boot process:

1. The master who puts the bricks and cuts must pay attention to observe whether the bricks follow the ruler during the cutting process and whether they leave the ruler.

2. During the cutting process, do not press the operation panel randomly. If you encounter an emergency brick breaking situation, press the red emergency stop button.

3. During the cutting process, do not touch the rollers at both ends of the belt with your hands, be careful to pinch your hands, and do not touch the cutting piece.

Ending matters after cutting:

1. After stopping work, press the emergency stop button.

2. Clean up the silt on the belt.

3. Check each position where the screw rod moves and put a little butter on it.

Foshan Nanhai Hongyun Ceramic Machinery Co., Ltd. is a ten-year-old company focusing on the production of ceramic deep-processing equipment and other deep-processing equipment for ceramic processing plants, integrating R&D, production, sales and installation process service enterprises. National door-to-door installation and training one-stop service, one-to-one door-to-door installation guidance and training operation technology, welcome to the factory for on-site inspection and consultation!