NEWS CENTER

Present the latest real-time information for you

The arc polishing machine integrates multiple functions, which can be used for edge grinding, grooving, chamfering, rounding, etc. It solves the problems of slow speed and excessive wear of the traditional manual tile edger and chamfering machine. It is mainly suitable for ceramic tile processing in a ceramic factory. The size of the processed arc surface can be adjusted at will, and the inclined surface of 45° can also be polished, and the product has high gloss. The processing cost is low and the effect is good.

The features of the automatic 14 large grinding head arc polishing machine:

1. Single swing structure-faster,cancels the wire rope structure and uses a bracket to make it more durable.

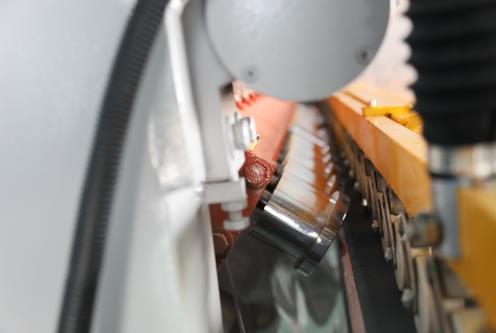

2. The 110mm large grinding head is more durable, and the grinding head is automatically lowered, saving labor.

3. The double trimming design has better processing effect, and the unique waterproof design concept focuses on durability.

Instruction manual for arc polishing machine:

One, wiring method:

A=FireWire B=FireWire C=FireWire; cable requirements: 16m2 copper wire

After the power is connected, the trimming motor is turned on when the machine is tested, and the motor rotates counterclockwise, which is a forward rotation. Otherwise, the adjustment method of reversal and reversal can be arbitrarily exchanged between the two live wires.

Second, Fill the water:

Need to prepare a 1.5KW sewage pump, caliber: 40mm;

Boot sequence and preparation steps:

1. Round edges + slotting:

(1) Add water first

(2) Turn on all power switches

(3)Adjust the size to be processed (press the "in" and "back" buttons)

(4) Trimming

(5) Slotting

(6)45 degree chamfer

(7)45 degree chamfer 2

(8) Shaped round wheel

(9) Swing

(10) Polishing motor No. 1-4.

2. 45 degree chamfer polishing:

(1) Add water first

(2) Turn on all power switches

(3) Adjust the size to be processed (press the "in" and "back" buttons)

(4)Trimming

(5)45 degree chamfer 1;

(6)45 degree chamfer 2;

(7) Polishing motor No. 1-4;

3. Chamfer the inner corner:

(1)Add water first

(2)Turn on all power switches

(3)Adjust the size to be processed (press the "in" and "back" buttons)

(4) Turn the bricks upside down, with the back facing up

(5)Press the pressure roller tightly

(6)Adjust trimming motor and shaping round edge wheel back!

(7)45 degree chamfer 1

(8)45 degree chamfer 2

(9) Put the automatic grinding head down (close or change to: manual)

1. There are automatic and manual modes for the grinding head down. The service life of the grinding head is about 5-10 hours. Pay attention to check whether the grinding head still exists.

2. The conveyor belt motor and the size-adjusting motor need to be oiled once every three months for maintenance. The grinding head spindle is turned on every day and a little oil is added to it.

3. The machine tool needs to be leveled and fixed.

Factory Address: No. 1 Park, Third Industrial Zone, Baishaqiao, Shishan Town, Nanhai District, Foshan City, Guangdong Province ,China.(Foshan Nanhai Hongyun Ceramic Machinery Co., Ltd. )